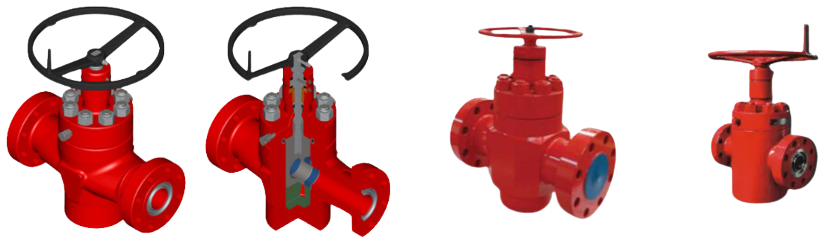

- FMH General Trading offers gate valves from size 1 -13/16″ to 7-1/16″ with pressure ratings from 2000 psi to 15000 psi.

- Design incorporates

- Spring-loaded, pressure-energized, non-elastomeric lip-seal between the seat and the body. This provides protection against the particle intrusion and prevents body erosion

- Minimum number of parts in the gate & seat assembly. One piece seat and gate ensures reliable sealing and ease of field service.

Metal to metal sealing between the gate and the seat. - Special spring-loaded, pressure-energized, non-elastomeric stem packing design.

- Stem shoulder that can be back seated against the bonnet to isolate the stuffing box. This allows field replacement of the stem packing while the valve is under pressure.

- Non-rising stem, supported by two needle roller thrust bearings, which prevents cavity pressure increase or displacement of cavity lubricant.

- Bottom retainer plate, provided as a gate guide during operations.

- For severe service applications, weld-clad or corrosion resistant alloy linings are applied to base forgings for maximum protection of the valve’s internal service area.

- We specialize in spares, services, repair, remanufacturing and troubleshooting for our valuable customers. All the service activities are carried out at FMH General Trading workshop or at field location.

- We provide a quick response to support our customers across the globe. Services and solution are catered by our well trained service engineers and technicians.

- We encourage customers to demand FMH General Trading services for repair, remanufacturing and servicing of other manufacturer. We provide complete engineering solutions, which includes design and manufacturing of new spares, assembly and pressure test if needed.

- Gate valves are primarily designed to start or stop flow, and when a straight-line flow of fluid and minimum flow restriction are needed. In service, these valves generally are either fully open or fully closed. The Gate in a Gate valve is completely removed when the valve is fully open; the Gate is fully drawn up into the valve Bonnet. This leaves an opening for flow through the valve at the same inside diameter as the pipe system in which the valve is installed. A Gate valve can be used for a wide range of liquids and provides a tight seal when closed.

- Manual Gate Valves suitable for well testing, high pressure drilling and production accompanied with sour gas or / and sand. These gate valves are designed, manufactured and tested in accordance with API 6A. Reasonable price and low cost of spares make them the most cost effective valve on the market.

Features

- Stem position indicator of non-rising stem valve is convenient for management.

- Designed, manufactured and tested in Accordance with API Spec. 6A.

- Integrally forged body

- The sealing surface of the gate are sprayed by carbide alloy at high velocity and seats are made of carbide alloy to enhance wear resistance, corrosion resistance and service life

- Gate to seat, seat to body, bonnet seal and stem backseat are metal to metal sealing

- Both thrust bearings with large load capacity and composite rubber-plastic stem lip packing reduces operating torque